PAX Family of Mixers

PAX Mixers

When It Comes to Mixers, Choose The Best

PAX Mixers were originally developed by PAX Water Technologies. With an installed base of several thousand mixers around the world and an average fleet age of seven years, the PAX family of mixers are the most frequently specified, lowest maintenance mixing systems in the world.

It's All in the Design

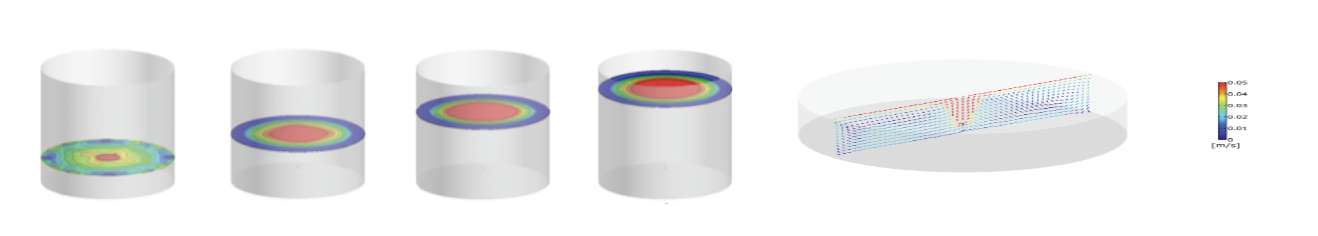

The PAX Mixer design is based on rigorous scientific analysis of fluid mechanical principles to achieve rapid disinfectant blend time. The patented and award‐winning PAX “lily impeller” embodies a design based on the energy transfer mechanisms observed in natural systems and is at the heart of PAX Mixer economy and efficiency.

Achieve Powerful and Reliable Mixing

Only active mixing can dependably provide the foundation for water quality improvement whether that consists of THM reduction, residual improvement or chloramine control. PAX Mixers can achieve powerful and reliable mixing regardless of tank geometry, size or location.

Designed by Nature, Backed by Science

"Nature never moves in a straight line, it tends to flow in a spiraling path."

Jay Harman, Founder of PAX Water

Biomimicry is a rapidly growing discipline in which nature’s solutions are adapted to solve man-made design challenges. At the core of PAX Mixers is the Lily impeller, named after its resemblance to the calla lily.

The Lily replicates nature’s spiral flow pattern – observed in whirlpools and tornados – to significantly improve the performance and energy usage of mixing water storage tanks.

While the Lily is only 8 inches (21 cm) tall, it is capable of circulating millions of gallons of water with the same energy footprint as three 100-watt light bulbs.

Any Tank. Any Size. We have a Mixer For You.

Regardless of tank size or disinfectant, we have the right mixer for you. Choose the mixer that best suits your process goal and tank size.

PAX Jet Mixers - For Small-to-Mid Size Tanks

PAX Jet Mixers create a powerful vortex flow pattern inside small-to-mid-size water storage tanks.

PAX Impeller Mixers - For Mid-to-Large Tanks

PAX Impeller Mixers are powerful and energy-efficient active mixers for mid-to-large tanks.

PAX Horizontal Mixers - For Large, Underground or Shallow Tanks

PAX Horizontal Mixers are ideal for large, underground water storage tanks and shallow tanks.

Tank Shark® Eductor Mixers - For Challenging Situations

The Tank Shark® Eductor Mixer provides a homogeneous mixture within the reservoir, eliminating thermal and residual stratification with no moving parts or electrical equipment within the reservoir.

PAX Mixers are designed for energy efficiency and engineered for ease of installation.

Four Reasons Why Every Tank Needs a PAX Mixer

Improves Disinfectant Residual Control

Mixers capable of rapid blend times are essential to accurately controlling residual when dosing disinfectant.

Reduces Tank Corrosion

Active mixing can lower head space temperatures inside tanks, decreasing corrosion in tank interiors.

Reduces Biofilm and THM Precursors

Active mixing combined with powerful aeration and ventilation can drive down THM levels in tanks.

Reduces or Prevents Ice Formation

Powerful active mixing can reduce or prevent ice formation in tanks to protect valuable tank assets.

PAX Mixers are Easy to Install and Maintain

PAX Water Mixers are easy to install and maintain – no heavy cranes, lifting equipment or tank alterations are required.

Before a mixer is installed, PAX Water recommends that the tank is drained, inspected and, if necessary, chemically cleaned – this returns the tank interior to its original as-built condition and ensures the best possible water quality.

PAX Jet Mixers are lightweight and easy to install by lowering the unit by the powercord through the hatch of the tank.

Learn how easy it is to install a PAX Mixer in this two minute video.

"PAX Mixers are the real deal - they immediately improved the uniformity of our water and allowed us to more thoughtfully add active water quality improvement measures."

Features of All PAX Mixers

- NSF61 certified

- Small footprint for easy installation

- 5-year warranty

- Integrates with Monoclor® RCS and PAX TRS™ THM Removal Systems

PAX Jet Mixers

PAX Jet Mixers create a powerful vortex flow pattern inside small-to-mid-size water storage tanks.

PAX Jet Mixers create a powerful vortex flow pattern inside small-to-mid-size water storage tanks.

PAX Jet Mixers vigorously circulate the tank volume to eliminate thermal stratification, and help to prevent ice formation, reduce residual loss and lower disinfection byproducts.

The mixer can be installed by lowering it into the tank from the hatch and self-rights once it reaches the tank floor, even on a sloped surface.

PAX Impeller Mixers

PAX Impeller Mixers are powerful and energy-efficient active mixers for mid-to-large size tanks.

PAX Impeller Mixers are powerful and energy-efficient active mixers for mid-to-large size tanks.

The Lily impeller was designed to mimic natural flow patterns observed in nature, such as ocean whirlpools, creating a vortex flow pattern that keeps water tanks well mixed while using very little energy.

PAX Impeller mixers are easy to install and maintain – no heavy cranes, lifting equipment or tank alterations are required.

If a municipality prefers to keep their tank full, PAX impeller mixers can easily be lowered through the tank hatch or installed by a diver.

PAX Horizontal Mixers

The PAX Horizontal Mixer is ideal for large, underground water storage tanks, where these long and shallow tanks have numerous support columns that prevent circulation and create high water age.

The PAX Horizontal Mixer is ideal for large, underground water storage tanks, where these long and shallow tanks have numerous support columns that prevent circulation and create high water age.

Tank Shark® Eductor Mixer

Tank Shark® Eductor Mixers provide powerful mixing for the most challenging situations.

Tank Shark® Eductor Mixers provide powerful mixing for the most challenging situations.

Patented Eductor Nozzle

The Eductor Nozzle puts out a 5 time flow increase to produce a 75-500 GPM upward flow utilizing 50 PSI motive water. This upward flow of water not only provides axial thrust, but also provides a rotational characteristic to the upward flowing stream.

Mixing Energy

The Tank Shark® Mixing System transfers its applied motive energy to the mass of water in the reservoir, placing it in motion. The nozzle motive energy functions to move colder water from the base of the reservoir up to and on top of the warmer stratified layers. This thermal disruption causes additional mixing beyond the energy associated with the nozzle itself. The extreme velocity at the nozzle discharge provides for self cleaning of the injection nozzles.

Homogeneous Reservoir

The upward rotational force of the Tank Shark® Mixing System achieves a homogeneous mixture and eliminates thermal stratification, aged water, ice, and prevents structural damage. For example, a Tank Shark® Mixing System can create a homogeneous mix in a one million gallon tank in 4 hours.

The Tank Shark® Mixing System provides for a homogeneous mixture within the reservoir, eliminating thermal and residual stratification with no moving parts or electrical equipment within the reservoir.

Benefits of PAX Mixers

Eliminates thermal and chemical stratification

Reduces disinfection byproducts (DBPs) and water age

Asset protection: Reduces ice formation and headspace corrosion

Featured Installations

Kaysville City

Location: Kaysville City, Utah

Goal: Ensure adequate disinfectant residual levels throughout their distribution system. They also wanted to test the use of mechanical tank mixers to see if they would evenly distribute chlorinated water throughout the tank and prevent low residuals downstream. They had six tanks. Each tank had volumes ranging from 1-2 million gallons.

Solution: PAX Impeller Mixers

Outcome: With the introduction of the PAX Impeller Mixers, the team was able to gain control over their residual levels in all six of their tanks. This new system can run 24/7/365 with great consistency, allowing the team to worry less about maintenance time and costs overall.

South Jordan

Location: South Jordan, Utah

Goal: Resolve their residual problems without having to resort to flushing or raising costs through other means. Avoid chemical stratification in water storage assets.

Solution: PAX Impeller Mixers

Outcome: The PAX Impeller Mixer generated enough mixing energy to satisfy their goals of maintaining consistent residual levels and raising the chlorine levels of certain areas in their tanks. The operators no longer had to worry about flushing water now that residual levels were balanced. South Jordan invested in additional mixers for multiple water storage tanks throughout their system.

City of Thousand Oaks

Goal: Address large seasonal swings across their 16 storage tanks. Maintain desired disinfectant residual levels, especially in reservoirs with low turnover. Manage high water age, reduced residual levels and elevated levels of nitrite in the winter. Test two mixers.

Solution: PAX Impeller Mixers

“Since the PAX Mixer has been installed, we’ve seen better residual at the top and bottom layers and have had great water quality; futhermore, nitrification levels dropped significantly.”

FAQs

Is there a limit to the size and shape of tank that can be mixed?

PAX Water has a family of active mixers that have been successfully installed and operated in a range of tank geometries and sizes. A single impeller mixer can effectively circulate reservoirs up to 25 MG and larger volumes can be mixed using multiple units. This includes complex designs, such as rectangular in-ground tanks with supporting columns and 120-foot-tall standpipes.

Can the PAX Water Mixer circulate the entire storage tank, even the bottom 3 feet of the tank?

The PAX Water Mixer circulates the entire tank, top to bottom – including the bottom 3 feet of the tank. PAX Water collects temperature and residual data measurements from multiple water levels in the tank to verify mixing performance.

How can a small 8-inch impeller circulate millions of gallons of water?

The heart of the PAX Water Mixer is our unique Lily impeller – a compact but highly efficient design for moving large volumes of water. The Lily replicates the vortex flow pattern observed in natural water bodies – such as lakes and ocean currents – the most effective and efficient method for mixing fluids while using very little energy.

What is the difference between “active” and “passive” mixing?

A passive mixing system can be a tank with a separated inlet and outlet or a set of piping and nozzles inside the tank that direct jets of water during the fill cycle. Passive mixing systems solely rely on tank fill and drain cycles to provide momentum for mixing. During periods of low demand, when mixing is most needed, passive systems often fail to fully circulate a tank. Active mixers operate on electric grid power to continuously mix tanks, day and night, year-round. This continuous mixing provides the most complete and thorough mixing for tanks and allows operators to keep tanks full without sacrificing water quality.

How is the PAX Water Mixer installed? Do I need to drain my tank or make tank modifications?

Does the PAX Water Mixer need to be installed in the center of the tank?

The PAX Water Mixer provides thorough mixing when installed below the hatch of a tank, even when the hatch is far from the center of the tank. Mixing performance will differ by no more than 20%, depending on the position of the PAX Water Mixer in the tank.

How does the PAX Water Mixer stay in place? Does it need to be fastened to the tank floor?

The PAX Water Mixer does not need to be attached to the floor of the tank. Each impeller mixer has three “gecko” feet – made of a durable, NSF-certified rubber – that grip onto the tank floor and keep the mixer stationary while remaining gentle on the tank’s interior coating. For tanks with a sloped floor, ask about our monopod jet mixers.

How long before I see results?

Thermal and chemical uniformity in a tank is typically established within the first 24 hours of mixer operation and will vary based on the tank shape and size.

Does the PAX Water Mixer come with chemical feed options?

PAX has several options for introducing disinfectant into the jet the mixer. PAX also has systems that can automatically monitor and dose tanks to keep disinfectant at a constant level.

Does the PAX system download to SCADA?

The PAX Water Mixer has SCADA connections available through RS-485 and through dry-contacts. SCADA outputs allow operators to easily monitor the status of the mixer remotely from their computers. Remote on/off functionality is also possible with the SCADA addition.

Is there a minimum water level for operating the PAX Water Mixer?

The PAX Water Mixer is 4-feet-tall and will turn off if the water level falls below the impeller or below the height of a jet mixer. For the mixer to work most effectively, we recommend a minimum of 6 feet of water in the tank to allow the mixer to set up a vortex flow structure. PAX also has a horizontal mixer that is ideally suited for shallow tanks.

Has the product been installed and tested in cold environments?

PAX Water Mixers have been installed and operated in extremely cold environments (with temperatures as low as -40 °F) and are effective at preventing ice formation inside tanks.

Does mixing help reduce disinfection byproducts like THMs?

A powerful active mixer with help remove some DBPs from your water storage tank. Active mixing circulates water that is high in DBPs to the water’s surface, where they are exposed to air in the headspace of the tank. PAX has installed systems where active mixing and ventilation alone are able to create a significant impact on DBP removal.

How do you predict disinfectant blend time performance?

PAX Water Technologies applies rigorous modeling and testing to predict and validate disinfectant blend time performance.

What is the maintenance of the PAX Water Mixer and how long will it last in the field?

The PAX Water Mixer requires very little maintenance. PAX Mixers come with a standard 5-year warranty. The majority of our impeller mixers (first installed in 2007) are still operating, so we advise customers to run the mixer to failure and then call PAX for a motor replacement.

Will mixing improve my chlorine residual?

Strong active mixing can help reduce residual loss in tanks. When tanks are unmixed, they become thermally and chemically stratified, which promotes the development of bacteria and biofilms in the upper portions of the tank. This biological growth can exert a high demand on residual disinfectant and we have often measured upper water layers with zero residual.

Active mixing helps bring fresh, disinfectant-rich water entering the tank into the upper water layers, which combats bacterial growth and biofilm formation. Strong active mixing also brings cooler water to the top of the tank, which slows the rates of chemical reactions that deplete disinfectant residual.

I’ve installed a mixer in my tank, how do I know it’s working?

Normal operation of the mixer can be confirmed by measuring electrical current draw or the readout from the control center. Additionally, depending on the location of the mixer, you may see gentle swirls of current as you look down from the hatch into the water, such as around the interior ladder (if one exists). These currents are a visible indicator of the strong convection created by the mixer.

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.